GARLIC PLANTING

One garlic at a time all planted by hand. Also note the barefoot woman.

When I looked carefully I could see that each bud of garlic was being planted about 1.5 inches away from the one next to it. And that whole field was being planted!

And the men work hard at keeping the machinery running in the fields.

ROAD BUILDING BY HAND

Here they are building or actually widening a country road outside of Heho. First the gravel or rocks are thrown against a screen to sort the rocks by size. This was being done by men.

Then, the men shoveled rock into the round tins (pans). The women would then put the filled pan on their head and walk to the section of road being built.

They then dumped the rock onto the road scattering it appropriately.

Here tar was being heated to later be spread onto the top surface of the road.

CORN PROCESSING

This is a corn “factory” in Heho. Here the women sort, cut, shuck, and bundle the corn.

SQUASHING BAMBOO

This woman is using this machine to squash strips of bamboo to extract the sugarcane juice and is then selling the sugarcane juice drinks.

STEVEDORES AT YANGON RIVER

On our first full day in Yangon Myanmar, we visited the jetty of the Yangon River (part of the Ayerwaddy River Delta). Here are four photos of stevedores carrying 125-pound sacks of rice, fertilizer, and construction sand to and from ancient riverboats. Note the stevedores are carrying sticks. Each stick represents one sack. They are paid by the number of sacks they transport.

BETEL QUIDS

This woman is preparing betel quids to sell. The large green leaves are betel leaves. She is wrapping areca nuts and tobacco in lime-coated betel leaves. Many Burmese men and women are addicted to chewing this leaving their teeth rotted and stained a blackish red.

STACKING COCONUTS

Watching this man set and balance his load and then take off with it was fascinating.

WEAVING

In Inle Lake lotus and silk weaving are done in a village “factory.” More details can be seen in my Inle Lake blog post.

BLACKSMITH VILLAGE

The Inle Lake blacksmith village is where old truck springs are shaped into machetes and plow blades. This is done by heating the metal and pounding with heavy sledgehammers by three to four men simultaneously.

CHAROOT FACTORY

Charoots are small mild cigars made from the leaves of a local tree.

The Burmese people are (in general) small but strong.

We ran into these two women after visiting an old abandoned monastery.

We ran into these two women after visiting an old abandoned monastery.

This is a tomato packing shed. This woman (and several others) was sorting tomatoes.

When we arrived in Pindaya, we drive in the countryside and took in the magnificent view.

Soon we saw a woman and a young boy with an ox cart in a field of cauliflower.

RICE PAPER & UMBRELLA MAKING

This little workshop is worked by three generations in this family.

The first step in this process is to pound mulberry bark to create the very thin “paper.”

Here the background paper is immersed in a solution and colored paper pieces are placed on it while it all floats in the water.

After the design is created, the whole frame is lifted and then set in the sun to dry.

This is what it looks like after it dries.

This is what it looks like after it dries.

To make an umbrella, a circular “spindle” is created. He first uses a foot powered lathe to create the original circular form. Then he has to saw twenty evenly spaced notches into it. Note how he is using his foot to guide his work. Also, check out the flipflops!

The spokes are then assembled.

Here the color is applied to the paper by hand. See the dye on her hands. The photo she is holding was presented to her by our in country guide who took the photo a year prior on another photography trip.

After watching the process I had to buy a few items. I would have loved to bring home this huge umbrella but I do not think it would fit in my luggage.

BRICK MAKING

While riding around we found this man making bricks one at a time by hand.

While watching the process Zeke wanted to try to make a brick. He did so with help from the expert.

Zeke said it was more difficult than it appeared. HAT MAKING

HAT MAKING

The people in the hat factory make all the hats from bamboo, then load the hats onto huge trucks to go to market. Note in this first photo how the women are doing the work of making the hats by first cutting the bark to the proper size and shape and the men are watching and taking care of the children.

Some more products made by hand by the Burmese

Silversmiths

And they even made this cover for the water cooler!

This whole street is devoted to carving and polishing marble statues. We wore face masks to keep from inhaling the dust.

This is a Gold Leaf Workshop where fit young men swung 6-pound hammers to flattened small pieces of gold into leaf much thinner than tinfoil. First a special paper must be made from bamboo, which separates the small squares of gold, one from another. It is a complex process and very labor intensive.

This is a Gold Leaf Workshop where fit young men swung 6-pound hammers to flattened small pieces of gold into leaf much thinner than tinfoil. First a special paper must be made from bamboo, which separates the small squares of gold, one from another. It is a complex process and very labor intensive.  Something that fascinated me was the timer. Note the yellow bowl on the wood plank. It is filled with water. A stick is attached to the inside bottom of half a coconut shell, which has a small hole drilled into the side. The water slowly seeps into the shell. When the shell sinks, the man or men doing the hammering know it is the end of that round of hammering.

Something that fascinated me was the timer. Note the yellow bowl on the wood plank. It is filled with water. A stick is attached to the inside bottom of half a coconut shell, which has a small hole drilled into the side. The water slowly seeps into the shell. When the shell sinks, the man or men doing the hammering know it is the end of that round of hammering.

More rice threshing – near Pyin Oo Lyin

Fan making

This young woman was cutting strips of bamboo for fans. As I took photos, she kept looking up at me and not watching what she was doing. I kept telling her to be careful and to look at the knife and not me. She was very adept at what she did. And, she kept smiling.

The fan factory. These fans are usually custom made as wedding favors or similar occasions.

Peanut Crushing near Bagan

This is a giant mortar and pestle used to crush peanuts into oil. The mortar is hollowed from a tree stump and the pestle is a heavy club turned round and round by an ox harnessed to it.

This man collects Toddy Palm juice twice a day by climbing to the top of the palm tree and cutting the ends off the palm flower, letting the sap run into pots. This is processed to become a very popular alcoholic beverage in SE Asia.

Here he showed us how he can climb this tree without a ladder and without shoes even though the bark is razor sharp!

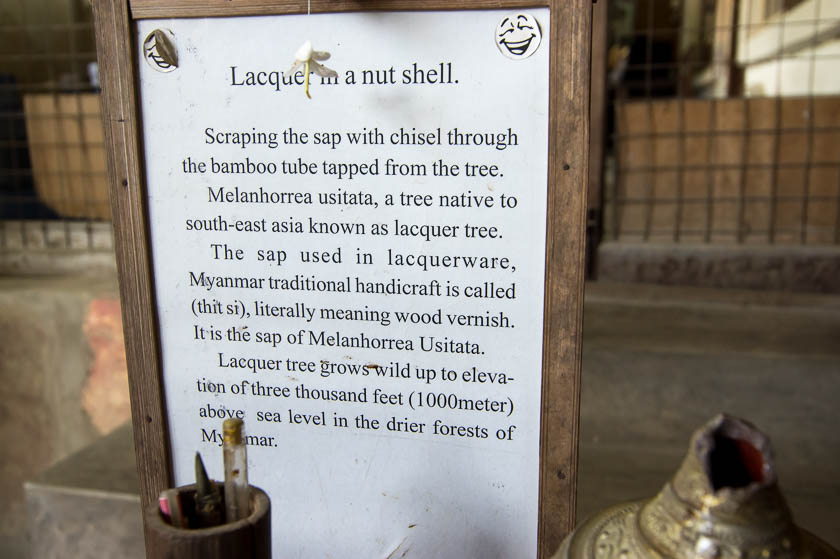

Making lacquer ware is an arduous, time consuming, precise, and artistic endeavor. After watching the process, though the pieces are expensive you must buy something.

I really wanted one of those as a centerpiece for my dining room table but getting it into my suitcase and paying the $2000 was what changed my mind.

I really wanted one of those as a centerpiece for my dining room table but getting it into my suitcase and paying the $2000 was what changed my mind.